Engineering Controls for Laboratory Safety

Learn about engineering controls used at UC San Diego to protect researchers from physical and chemical hazards.

Purpose

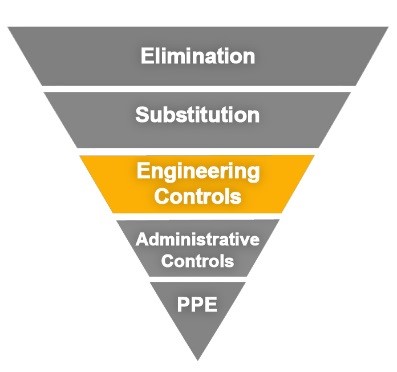

Engineering controls are often used with administrative controls and personal protective equipment. Engineering controls are used to remove a hazard or place a barrier between the employee and the hazard. Administrative controls are changes in work procedures with the goal of reducing the duration, frequency, and severity of exposure.

All manufacturer-installed safety engineering controls must be in place and functioning as intended. Additional controls may be required depending on the nature of the equipment and its functioning environment.

Read about engineering controls at UC San Diego:

Engineered Safety Equipment Overview

See Engineered Safety Equipment – What’s the Difference? for an overview of our common equipment.

Building ventilation

The primary functions of ventilation systems are to provide safe, comfortable, breathable environments for all employees and the public, and to minimize exposures to hazardous air contaminants. Careful planning, designing, and maintaining air supply and exhaust vents and equipment can accomplish these goals.

All laboratory spaces shall have mechanically generated and conditioned supply and exhaust air. All lab rooms shall exhaust 100% to the outside. There shall be no return of fume hood and laboratory exhaust back into the building. Building ventilation provides systems at UC San Diego laboratories with at least 6 air changes per hour (ACH) of fresh (outside) air. This volume of airflow reduces possible employee exposure to airborne contaminants and removes excess heat. It also directs airflow from areas of lower hazard to areas of higher hazard, which helps keep odors, dusts, and vapors out of hallways and other public areas.

Emergency override buttons (EOBs)

Some laboratories install emergency override buttons (see image at right) to provide maximum room ventilation in the event of a chemical emergency that impacts laboratory air. Only activate this button if you feel laboratory air has been impacted by a chemical emergency.

- To activate:

- Open the clear cover and push where it says PUSH HERE. Once activated, room air supply and exhaust will be ramped up to maximum capacity to ventilate the space.

- Evacuate all personnel from the space immediately. Stay out until the room is cleared for reentry.

When the button is pushed, UC San Diego Police and Environment, Health & Safety will be contacted to investigate. To ensure rapid response:

- Contact UC San Diego Police after activating the EOB:

- Call 9-1-1 from campus phones.

- Provide the police with any useful information.

When the issue has been resolved, the EOB will be deactivated by authorized personnel and the space will be declared safe for reentry.

Local exhaust systems and fume hoods

A local exhaust system is a device that captures contaminants at their source before they escape into the workroom environment. Drafts, traffic, and heating sources can impair the effectiveness of a local exhaust system. These systems are required to be certified annually as to their effectiveness.

To be effective, the hood must be within 10–12 inches of the source (closer is better). Drafts, traffic, and heating sources can impair the effectiveness of a local exhaust system.

- Chemical fume hoods contain hazardous

dusts , gases, vapors, and fumes that are generated within them and remove them via the building's ventilation system. When used properly, these hoods are extremely effective at protecting lab workers and the work environment. Fume hoods must not be used with biohazardous materials since it is a non-sterile environment and not designed for this type of hazard.

- See Chemical Fume Hoods for more information.

- Wash down fume hoods, or perchloric fume hoods, are designed with a wash down feature that will remove damaging corrosive residues, and in the case of

percholoric acid, potentially explosive perchlorate salts from thehume hood, ductwork, and fan. - "Snorkel" or "elephant trunk" exhaust systems are flexible arms with cones on the end that can be positioned directly over your work. Intended for small areas or machines, each snorkel exhaust has its own air damper. The effective range of snorkel exhaust is typically less than a foot and must be reviewed by EH&S prior to installation.

Biological safety cabinets (BSCs)

A biological safety cabinet (also called biosafety cabinet) is an enclosed, ventilated laboratory workspace for safely working with materials contaminated or potentially contaminated with pathogens.

A biological safety cabinet (also called biosafety cabinet) is an enclosed, ventilated laboratory workspace for safely working with materials contaminated or potentially contaminated with pathogens.

BSCs use HEPA filters to protect lab workers and the environment from aerosols or droplets that could spread biohazardous material. Biosafety cabinets are required to be certified annually.

- See Biological Safety Cabinets for more information.

Animal transfer station

Animal transfer and cage changing stations are portable downdraft-filtered laminar flow benches (clean benches) that have been specifically modified for small rodent handling and cage changing. These stations provide improved laboratory animal allergen control from dust and dander while performing animal husbandry activities. These units are not designated as a biosafety cabinet and should not be used for work with potentially infectious materials, toxins, or volatile chemicals. Please coordinate the use of this equipment with the Animal Care Program (ACP) and Vivarium Safety.

Shielding for radiation

Radiation shielding varies from lead bricks to plastic (Lucite) panels, depending on the type of radiation involved. Different thicknesses of these materials are used, depending on the energy of the radiation. See how to use lead shielding safely.

Radiation shielding varies from lead bricks to plastic (Lucite) panels, depending on the type of radiation involved. Different thicknesses of these materials are used, depending on the energy of the radiation. See how to use lead shielding safely.

Blast shield

Portable blast shields provide additional protection when working with reactive materials.

Whenever a potentially explosive reaction is being carried out (such as generation of diazomethane) or the use of pressurized equipment is involved, a safety shield should be used to provide added protection against an implosion.

Glove boxes

Glove boxes are airtight boxes with 2 or more heavy rubber gloves and an airlock.

Glove boxes are airtight boxes with 2 or more heavy rubber gloves and an airlock.

Use them when working with known carcinogens and highly toxic substances, or to provide an inert atmosphere for compounds that are sensitive to water or air. Glove bags are an economic alternative for short-term uses.

Gas cabinets

A fully enclosed, non-combustible exhausted enclosure used to store or use gas cylinders. It operates at

Laminar flow clean bench

A clean bench is a ventilated workspace designed to prevent contamination of product or semiconductor wafer from the laboratory environment or workers. This type of equipment also includes devices such as PCR hoods and clean benches. Air is drawn through a HEPA filter and delivered in a laminar (non-turbulent) flow across the work surface towards you.

Clean benches DO NOT protect people or the environment. LFHs should only be used for work with non-infectious materials or non-volatile chemicals. If you work with hazardous materials, use a fume hood or biosafety cabinet instead.

Downdraft tables

Downdraft tables are workstations with built-in ventilation that pulls air, odors, vapors, and aerosols down and away from the worker's face. They are used primarily for dissections of formaldehyde-preserved specimens and for capturing dust, vapors, or other contaminants from fabrication activities.

Downdraft tables can be quite large and difficult to access from all sides. The capture efficiency can be affected by changing conditions in the room. Keeping the filtration system clean and operating properly can be difficult.

Rotary evaporators

Rotary evaporators, also called rotavaps, remove solvents from reaction mixtures. A condenser traps solvents under a vacuum, which allows for easy reuse or disposal of a collection. A vacuum line, a circulation bath or a membrane pump can be used as source for the vacuum.

Rotary evaporators, also called rotavaps, remove solvents from reaction mixtures. A condenser traps solvents under a vacuum, which allows for easy reuse or disposal of a collection. A vacuum line, a circulation bath or a membrane pump can be used as source for the vacuum.

Even with simple operations such as evaporation, hazards can exist. Users of rotary evaporation equipment must take precautions to avoid contact with rotating parts, particularly entanglement of loose clothing, hair, or necklaces. Rotating parts can draw the users into the apparatus resulting in breakage of glassware, burns, and chemical exposure. Extra caution must also be applied to operations with air reactive materials, especially when under vacuum. A leak can draw air into the apparatus and a violent reaction can occur.

Vacuum line protection

Vacuum systems (both centralized and stand-alone pumps) are commonly used to help researchers filter reagents and dispose of waste. It is very important to protect your vacuum system from biohazards and chemicals routinely used in research. Vacuum systems protect labs, building staff, and the environment from liquid contamination and dangerous aerosols.

- House vacuum systems must be protected from biological materials/chemicals by filters.

- Protect the vacuum lines and pump with a trap.

- Belts and pulleys on the pump must be guarded (covered).

- Avoid risk of implosion by using vacuum-rated glassware. Standard glassware may implode when subjected to vacuum.