Managing Photo and X-ray Processor Equipment

Last Updated: April 3, 2024 4:25:22 PM PDT

Give feedback

Properly manage photo and x-ray processing waste, including spent silver-rich fixer, developer solutions, and other processing materials.

Photo and x-ray processor equipment requires special handling and oversight to properly manage stock chemicals, spent silver-rich fixer, developer solutions and other processing materials. Compliance falls under state and local hazardous materials and discharge permits.

PI, area manager, and department responsibilities

Post all 4 items near photo and x-ray processor equipment:

- SDS posted by vendor

- Appendix D available from EH&S

- Service log sheets posted near equipment

- Vendor contact information

Ensure equipment is managed properly:

- Equipment must be serviced every 3 months

- Onsite Treatment uses Chemical Recovery Cartridge (CRC)

- Must be replaced every 12 months

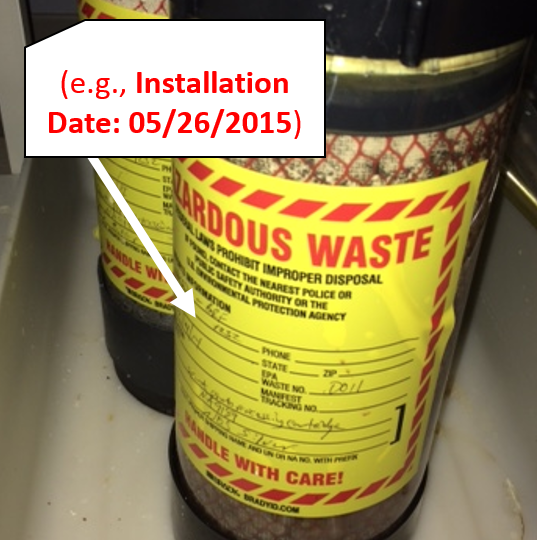

- Each cartridge must be clearly marked with the date of when it was first installed.

- Each cartridge must be labeled: Silver Recovery Cartridge

- Cartridges must be in secondary containment.

- Verify service logs are maintained with dates, including types of service performed, cartridge change out and volume of waste hauled off-site.

- Retain copies of all receipts and contracts for silver recovery equipment service, and manifests for off-site solution disposal for a period of 3 years.

- Stock containers of developer, fixer and cartridges must be:

- Stored in secondary containment

- Properly labeled

- Drain service contract must be coordinated with FM to ensure drains are regularly cleaned out twice per year. Facilities Maintenance pays for 1 one clean out (the department is automatically billed for the remaining one). Responsible party must initiate the scheduling of clean outs with Facilities Management.

Vendor responsibilities

- Vendor must post their contact information.

- Follow posted Appendix D BMP.

- Install 2, in-line cartridges at each equipment unit. Stagger cartridge replacement and move back cartridge to front, installing a new cartridge in the second position.

- Replace each chemical recovery cartridge (CRC) every 12 months

- Mark each cartridge with the date of when it was first installed and labeled “Silver Recovery Cartridge.”

- Treat waste on-site following silver-rich solution management requirements stated on Appendix D BMP; or waste is hauled off-site following all local and state regulations.

- Service every 3 months and fill out log sheets properly when servicing equipment. Log sheets must include, types of service performed, cartridge change out and volume of waste hauled off-site.

References

For more information, contact the EH&S Environmental Management Facility, (858) 534-2753.

Notice: Disposal of hazardous waste using sinks, intentional evaporation, or as regular trash is against the law. Campus laboratories must abide by strict state and federal waste disposal requirements. You may be held liable for violations of applicable laws.