Laboratory Drain Protection

Last Updated: September 27, 2020 3:28:00 PM PDT

Give feedback

Learn how to best manage and protect laboratory drains from hazardous waste.

Requirements

- Do not dispose of hazardous waste to the sewer or storm drain; such disposal is strictly prohibited. For assistance in determining whether a waste is hazardous, contact EH&S Environmental Management Facility at hazwaste@ucsd.edu or (858) 534-2753 or refer to the types of hazardous waste.

- Prevent leaks or spills from accidentally entering the sewer.

- Drain protection can be accomplished through one of the following options:

- Move the fluids to an area from which they could not flow into the drains.

- Plug the drains or cap the drain pipes, as applicable.

- Install a raised lip or curb around the drains or extend the drain pipes, a minimum of four inches above any area features which could contain fluids.

- Construct spill containment for the fluids,

of capacity equal to the largest fluid vessel plus any fire water volume required by fire codes, and exclude the drains from the containment area.

- Drain

plugs, raised lips, drain curbs, or containment walls must be of a permanent nature and materials resistant to corrosion by the fluids, e.g. epoxy grout or epoxy coated concrete. Drain pipe caps or extensions must be welded or glued. - Never use sinks as secondary containment or for chemical storage.

- Eliminate or reduce single-pass water to less than 500

gpd . - All biohazardous medical wastes must be managed and discharged in compliance with the January 2016 California Medical Waste Management Act and revisions and amendments thereto, as set forth in the California Health and Safety Code, Sections 117600-118360 (PDF).

Waste Minimization

- Substitute less toxic materials in production and cleanup operations when feasible.

- Order chemicals in the minimum quantities necessary for a process/ protocol; this eliminates waste resulting from the process changes and expiration dates passing.

- Work with the minimum amount of chemicals required by the process/ protocol; this reduces waste in the event of a spill and encourages prudent chemical handling.

- Reuse/ Recycle spent solvents when possible.

- Practice water conservation by installing flow restrictors and recycling water when possible. Use DI water only for final rinsing?

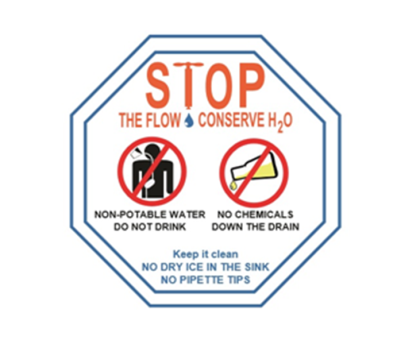

Drain Protection

- Utilize secondary containment to prevent leaks or spills from accidentally entering the sewer. Trays or plastic holders can be used for small volumes; larger volumes should be stored in bermed or diked storage areas. Secondary containment should be kept dry. Never store incompatible chemicals together in the same containment area. Other spill prevention measures include:

- Using coated containers to reduce spills caused by breakage.

- Storing chemicals in latched cabinets and using shelf barriers.

- Checking storage container integrity on a regular basis.

- Storing chemicals in approved cabinets or on lower shelves.

- Maintaining a written spill response plan and be sure that all employees are familiar with it. Be sure that spill cleanup supplies are adequately stocked and easily accessible.

- Keep a mercury spill cleanup kit in labs where mercury is used. Consider substituting electronic sensing devices for mercury-containing equipment to prevent spills associated with accidental breakage. Mercury in thermometers is the most likely source of this contaminant in labs.

- Most importantly, familiarize yourself with What Can Go Down the Drain.

Other

- Practice good housekeeping by cleaning up spills immediately, clearly labeling all containers, utilizing proper chemical storage practices, and keeping clutter to a minimum.

- Film Processing: Refer to managing photo and x-ray processing equipment.

EH&S Environmental Affairs Compliance Officer (858) 534-9695