Laser Safety Program: Laser Hazard Control Measures

Last Updated: February 29, 2024 5:10:21 PM PST

Give feedback

Use laser hazard control measures to eliminate or reduce the possibility of eye or skin exposure to hazardous levels of laser radiation and other ancillary hazards.

Controls required by the Laser Safety Program are determined by the hazard classification of a laser or laser system and how and where it will be used.

Hazard control measures

Implement control measures that reduce hazards associated with your laser devices during normal operation and maintenance.

- Include mitigation procedures for:

- Beam hazards

- Non-beam hazards

- Biological hazards

- Consider conditions necessary for safe laser operation when devising hazard control measures:

- Anticipate potential eye exposure during alignment

- Ensure optics are aligned

- Use appropriate eye protection

- Ensure safe methods of handling high voltage

- Prevent unprotected personnel from entering the laser area

- Ensure new operators are trained in safety procedures

- Anticipate and provide protection for ancillary hazards

- Double-check proper restoration of equipment following service

All laser classifications

Class 1, 1M, 2, 2M, and 3R lasers are generally exempt from control measures and medical surveillance; however, at UC San Diego, follow the general engineering control measures below for all laser uses and systems:

- Use the minimum laser radiation level required for the application. If a laser or laser system emits excessive radiation, the EH&S Laser Safety Officer (LSO) may order a reduction of power to a level commensurate with the required application.

- Maintain the laser beam at a height other than the normal sitting or standing position of a person.

- Use protective housing on all lasers and laser systems.

- Note: In certain instances, operation of a laser or laser system without a protective housing may be necessary. In these cases, contact the Laser Safety Officer, (858) 822-2850, to arrange alternative control methods.

- Perform alignment of laser optical systems so that the primary beam, specular, or diffuse reflection does not expose the eye above the applicable maximum permissible exposure (MPE) limit.

- Use an alignment laser whenever possible, or use the lowest power setting during alignment.

- Contact the Laser Safety Officer, (858) 822- 2850, if you have questions about MPE.

- Evaluate non-beam hazards and incorporate mitigation procedures into your Laser Safety Plan.

Class 3B and 4 lasers and laser systems

Use the required engineering control measures described below for class 3B and 4 lasers and laser systems. Other controls, not designated as required, are strongly recommended.

- Interlocks on protective housing are required for class 3B and 4 lasers. Interlocked protective housing is activated upon removal of the protective housing during operation and maintenance. The interlock is designed to prevent access to the beam above the applicable maximum permissible exposure (MPE) limit.

- Remote interlock connectors are required for class 4 lasers and strongly recommended for class 3B lasers. Interlocks facilitate electrical connections to an emergency master switch. When the terminals of the connector are open circuited, the accessible radiation must not exceed the appropriate MPE levels.

- Key control is required for class 4 lasers. Restrict the key or code that enables operation of a class 4 laser or laser system to an appropriate supervisor or authorized laser operator. Disable the master switch when the laser is not in use.

- Viewing portals and diffuse display screens, which are part of a laser or laser system, must incorporate a suitable means (such as interlocks, filters, or attenuators) to maintain the laser radiation at the viewing position at or below the applicable MPE.

- Collecting optics (lenses, telescopes, microscopes, etc.) intended for viewing use with a laser or laser system must incorporate suitable means (such as interlocks, filters, or attenuators) to maintain the transmitted laser radiation at levels at or below the appropriate MPE.

- A completely exposed or partially exposed beam path from a class 3B or 4 laser or laser system requires the EH&S Laser Safety Officer to conduct a hazard analysis to establish the Nominal Hazard Zone (NHZ) if not furnished by the manufacturer.

- A beam stop or attenuator is required for class 4 lasers and is strongly recommended for class 3 lasers. The beam stop or attenuator must be capable of preventing laser radiation in excess of the appropriate MPE level.

- Built-in activation warning systems for class 4 lasers and laser systems may include audible sound (bells or chimes), warning lights, or verbal countdown. An audible warning system notifies personnel that the laser is either about to be activated or deactivated.

Practice special control measures for invisible laser radiation if infrared or ultraviolet radiation is involved.

Invisible laser radiation

Since infrared and ultraviolet radiation is invisible, follow the special precautions described below for these laser systems, in addition to the laser control measures required by hazard classification.

- Use a visible coaxial aiming beam, if possible, or a phosphorus card for alignment.

- For infrared lasers (IR):

- Terminate the beam from class 3B IR lasers with a highly absorbent backstop.

- Terminate the beam from class 4 IR lasers with a fire-resistant material.

- Note: Select materials carefully. Many surfaces which visually appear "dull" can act as a reflector of infrared radiation.

- For ultraviolet (UV) lasers:

- Use appropriate shielding materials to attenuate the radiation level below MPE for the specific UV wavelength.

- Be alert to the possibility of producing hazardous by-products, such as ozone, and the formation of skin sensitizing agents.

- Caution: Toxic gases, such as F2, Cl2, NF3, etc., may be produced with the use of UV lasers, and should be guarded against when invisible radiation is accessible from a class 3 or class 4 laser system.

- Display warning signs and/or lights in a conspicuous location to alert personnel in the area when then the laser is activated.

Laser optical fiber

Laser systems which employ optical fiber are considered enclosed systems with the optical fiber forming part of the enclosure.

- Take these special precautions in addition to the laser control measures required by hazard classification:

- If disconnection occurs and the resulting laser radiation is below the applicable MPE by engineering controls, connection or disconnection can be done in an uncontrolled area.

- Connection or disconnection must be done in an appropriately controlled area during operation if the laser radiation is greater than the applicable MPE.

Warning signs and labels

Laser hazard signs are posted on laser control area entrances. Labels are used on laser equipment.

Laser hazard signs and labels must meet American National Standard (ANZI) Z535, Specifications for Accident Prevention Signs, ANSI Z534 series, latest revision. Signs and labels prepared in accordance with previous standards are acceptable. Environment, Health & Safety (EH&S) provides signs and labels to UC San Diego researchers upon request.

Follow the label and signage requirements below:

- Laser hazard signs:

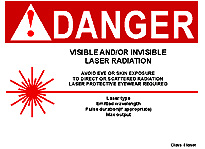

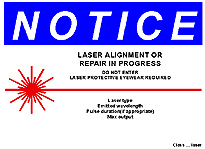

Laser Hazard label and signage requirements

Laser hazard sign Laser alignment or repair sign - Post all entrances to laser control areas with laser hazard signs.

- Use the signal word "Danger" on all signs and labels associated with class 3R lasers or laser systems that exceed the appropriate MPE for irradiance, and all class 3B and 4 lasers and laser systems. (See red image above.)

- Use the signal word "Notice" on all signs posted outside temporary laser control areas, such as during alignment, service, or repair. (See blue image above.)

- Print or legibly write specific information at the following 3 positions on a laser hazard sign:

- Position 1, above the tail of the sunburst – Describe special precautionary instructions or protective actions. This may include the following elements:

- Required protective eyewear

- Invisible laser radiation

- Knock before entering

- Do not enter when light is on

- Restricted area

- Position 2, below the sunburst tail – Indicate the following information, as applicable:

- Type of laser (i.e., YAG, Helium-Neon, etc.)

- The emitted wavelength

- Pulse duration (if appropriate)

- Maximum output

- Position 3, lower-left corner – Indicate the class of the laser or laser system.

- Position 1, above the tail of the sunburst – Describe special precautionary instructions or protective actions. This may include the following elements:

- Request signs and labels as needed from the EH&S Laser Safety Officer, (858) 822-2850.

Repairs and maintenance

Observe precautions during repairs and maintenance:

- Allow maintenance and repair work on laser systems to be performed only by certified service personnel who have documented training for the laser system to be serviced.

- Ensure repair and service personnel take appropriate safety precautions to protect themselves, lab personnel, and the general public within the vicinity.

- Post a sign with the signal word "Notice," (see image below) in a conspicuous location outside the laser control area to indicate repairs or alignment procedures are underway.

- State pertinent safety information on the sign. Read about warning signs above for details.

- Post the sign for the duration of service or repair.

Laser alignment or repair sign

Standard operating procedure

A written standard operating procedure (SOP) is required for class 4 lasers and strongly recommended for class 3B lasers.

- Read Requirements for Class 3B and 4 Lasers for specific SOP requirements.

- Keep the SOP easily accessible for operators and service personnel.

Indoor laser control areas

Indoor laser control area requirements apply to facilities where class 3B and 4 lasers or laser systems are used.

- Determine the status of your facility by doing the following:

- Contact the EH&S Laser Safety Officer, (858) 822-2850, to conduct an analysis of your facility. If the analysis determines that a class 3B or 4 laser will be used, a laser control area will be established.

- For class 3B indoor control areas: These measures are required for class 3B lasers, and advisory for class 3R lasers.

- Restrict access. Keep doors locked to prevent unauthorized access to the control area.

- Post laser hazard warning signs on entrances to the controlled area.

- Permit only authorized, trained personnel to operate the laser equipment.

- Admit untrained personnel or spectators only if authorized by the laser operator, under supervision, and after they have been informed about safety requirements and provided with protective eyewear (if required).

- Place special emphasis on control of the beam path if the laser beam is not enclosed.

- For class 4 indoor laser control areas: High-power lasers require extra control measures due to greater risk of injury from the direct or specular reflected beam, and hazardous diffuse reflections.

Implement the class 4 precautions below in addition to the measures described above:

- Locate class 4 lasers in an area designed solely for laser operation.

- Control the entire beam path capable of producing hazardous reflections.

- Install safety locks or interlocks to deactivate the laser in the event of an unexpected entry into the laser control area.

- Design the interlock to allow both rapid egresses by the laser personnel and admittance under emergency conditions.

- Enable the individual in charge of the control area to momentarily override the room access interlocks.

- Design an override feature that prevents automatic re-energizing of the power supply and requires the manually resetting power to the shutter.

- Install a control-disconnect switch, or "panic button," for deactivating the laser.

Outdoor laser control areas

All class 3B and 4 lasers energized outdoors for entertainment or scientific purposes are subject to the requirements below.

- Obtain permission to operate lasers or laser systems outdoors on UC San Diego property from the LSO prior to initial use.

- Submit a written request to the EH&S Laser Safety Officer at Mail Code 0089.

- Design the laser control area to prevent any scatter or reflected laser radiation from exiting the area.

- Configure the beam path so it's inaccessible to audiences or pedestrians.

- Secure power sources and wires to prevent tripping or other inadvertent accidents.

For more information, contact EH&S Laser Safety, (858) 822-2850 or 822-2494.